Vapor Gasket heat exchanger

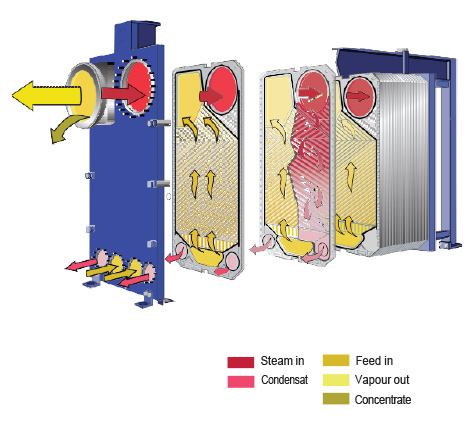

How it works

Vapor GPHE is purpose-built for evaporation, featuring two compact inlet feed connections and a spacious outlet dedicated to vapor and concentrate. It is equipped with one sizable inlet and two smaller outlets for condensate. The design of Vapor GPHE incorporates plates welded in pairs, allowing for effective condensation of heating steam in the welded channel, while the evaporated product smoothly flows through the gasketed channels.

Benefits

Enhanced thermal conductivity

The arrangement of corrugated plates induces intense turbulence, resulting in significantly higher heat transfer efficiency compared to traditional

shell-and-tube evaporators. Vapor GPHE excels particularly in scenarios with high concentration and viscosity, effortlessly handling temperature variations as low as 3–4°C. This quality proves exception- ally advantageous when integrated into TVR and MVR systems.

Minimal fouling and effortless maintenance

The extensive plate turbulence enables highly effective chemical cleaning procedures. Due to the reduced volume capacity, only minute quantities of cleaning agents are necessary in comparison to shell-and-tube systems. Furthermore, the flexible design of Vapor GPHE ensures easy accessibility to heat transfer surfaces for inspection or mechanical cleaning.

Flexible capacity expansion

One prominent advantage of Vapor GPHE is its capability to increase or decrease capacity by adding or removing cassettes within the existing framework. This feature stands in stark contrast to shell-and-tube evaporators, where capacity remains fixed upon installation.

Saving

The remarkable heat transfer efficiency translates into a substantial reduction in required heat transfer surface area compared to shell-and-tube evaporators. Consequently, Vaper GPHE becomes highly cost-effective, especially when dealing with demanding materials like SMO, titanium, nickel, and Hastelloy.

Additionally, the compact and adaptable design of Vapor GPHE greatly diminish- es expenses related to transportation, assembly, and installation when compared to shell-and-tube units.

Enhanced product quality

The exceedingly low hold-up volume within Vapor GPHE means that only a negligible amount of product remains inside the evaporator at any given time. This brief exposure time to the evapora- tor proves highly beneficial for heat-sen- sitive products, ensuring improved product quality.

Applications

• Biotech and Pharmaceutical

• Chemicals

• Energy and Utilities

• Food and Beverages

• Water and Waste treatment

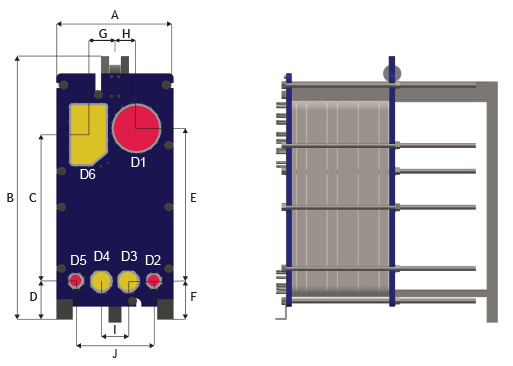

Dimensional drawing

Technical data

|

Plate Type |

Free channel, mm |

|

Semi-welded |

6 / 6.5 |

|

Materials |

10 |

|

Heat transfer plates |

316/316L, 904L, 254 |

|

Field gaskets |

NBR, EPDM |

|

Ring gaskets |

NBR, EPDM, FKM |

| Flange connections | Metal lined: stainless steel, nickel, titanium |

| Frame & pressure plate | Carbon steel with painted |

|

Model |

A |

B |

C |

D |

E |

F |

G |

H |

I |

J |

D1 |

D2/D5 |

D3/D4 |

D6 |

|

EC350 |

1160 |

2610 |

1430 |

385 |

1576 |

394 |

271 |

252 |

290 |

806 |

350 |

DN100 |

DN150 |

DN350 |

|

EC500 |

1160 |

2610 |

1509 |

394 |

1532 |

438 |

278 |

223 |

290 |

806 |

400 |

DN100 |

DN150 |

DN500 |

|

EC650 |

1380 |

3210 |

2028 |

430 |

2158 |

414 |

294 |

329 |

300 |

913 |

450 |

DN150 |

DN150 |

DN650 |

Operational data

|

Max. design pressure |

Max. design temperature (°C/°F) |

|

6.0/ 8.0 barg |

180/356 |

Extended pressure and temperature rating may be available