Gasket Plate and Frame heat exchanger

Introduction

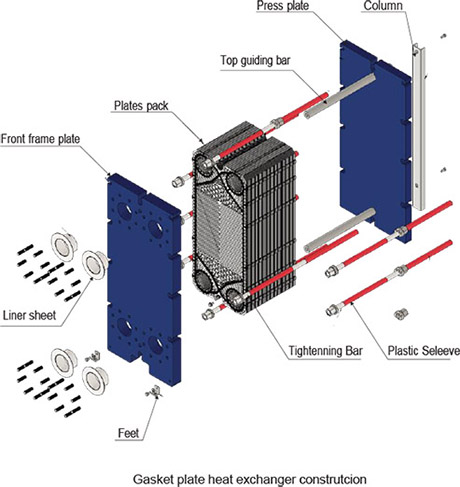

A gasketed plate heat exchanger is a type of heat exchanger that consists of a series of corrugated metal plates sealed together with gaskets. The plates are typically made of stainless steel or other materials with good heat transfer properties. The gaskets, usually made of elastomer or other compatible materials, create a seal between the plates and ensure that the fluids remain separate.

Benefits

• High energy efficiency – low operating cost

• Flexible configuration – heat transfer area can be modified

• Easy to install – compact design

• High serviceability – easy to open for inspection and cleaning and easy to clean by CIP

Features

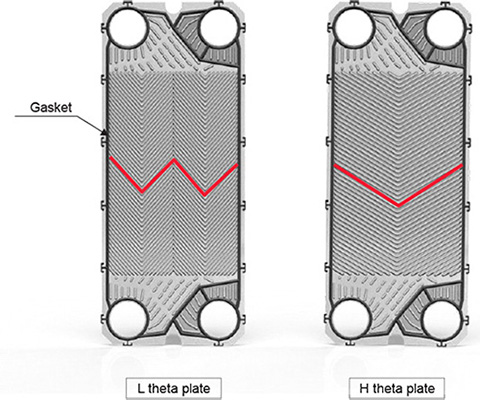

• Gaskets and Sealing:

• Counter-Current Flow:

• Flexibility and Modularity:

• Easy Maintenance and Cleaning:

Applications

• Biotech and Pharmaceutical

• Chemicals

• Energy and Utilities

• Food and Beverages

• Home and Personal care

• HVAC and Refrigeration

• Machinery and Manufacturing

• Marine and Transportation

• Mining, Minerals and Pigments

• Pulp and Paper

• Semiconductor and Electronics

• Steel

• Water and Waste treatment

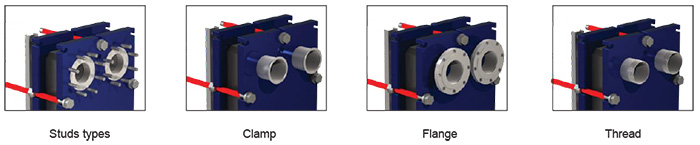

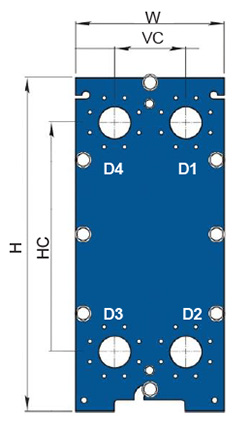

Connections Available

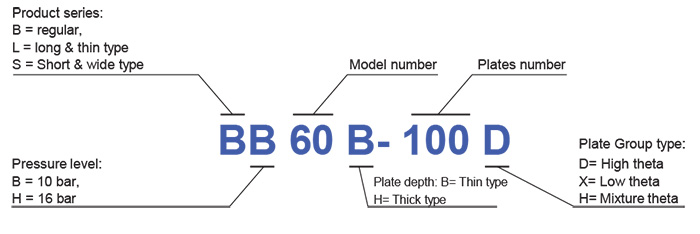

Model Code Explaination:

|

Material | |||

| Plates | 304, 316L, SMO, C276, NI, Titanium | |||

| Gaskets | NBR, EPDM, FKM | |||

| Flange connections | Carbon steel, Stainless, Titanium, Rubber lined | |||

| Frame plate | Carbon steel, epoxy painted | |||

| Flow direction: | ||||

| Hot In: D1 -> Hot out: D2 , Cold In: D3 -> Cold Out: D4 Hot In: D4 -> Hot out: D3, Cold In: D2 -> Cold Out: D1 |

||||

|

Model |

W |

H |

HC |

VC |

Free channel |

Connection Standard |

|

B30B |

180 |

480 |

60 |

357 |

2.5 |

DN25 |

|

B60B |

320 |

920 |

140 |

640 |

2 |

DN50 |

|

B60H |

320 |

920 |

140 |

640 |

3 |

DN50 |

|

B100B |

454 |

1045 |

225 |

719 |

2.55 |

DN100 |

|

B100H |

454 |

1045 |

225 |

719 |

3.95 |

DN100 |

|

B150B |

610 |

1815 |

298 |

1294 |

2.5 |

DN150 |

|

B150H |

610 |

1815 |

298 |

1294 |

3.95 |

DN150 |

|

B200B |

780 |

2260 |

353 |

1478 |

2 |

DN200 |

|

B200P |

780 |

2260 |

353 |

1478 |

|

DN200 |

|

B200H |

780 |

2260 |

353 |

1478 |

4 |

DN200 |

|

B250B |

920 |

2903 |

439 |

1939 |

2.5 |

DN250 |

|

B250H |

920 |

2903 |

439 |

1939 |

4 |

DN250 |

|

B300B |

1150 |

2882 |

596 |

1842 |

3.2 |

DN300 / 350 |

|

LB60B |

320 |

1264 |

140 |

1036 |

2 |

DN50 |

|

LB100B |

480 |

1888 |

225 |

1338 |

2 |

DN100 |

|

LB100P |

480 |

1888 |

225 |

1338 |

3 |

DN100 |

|

LB150B |

610 |

2752 |

288 |

2035 |

2.5 |

DN150 |

|

LB350B |

1154 |

3210 |

578 |

2177 |

2.5 |

DN300 / 350 |

|

SB60H |

400 |

704 |

203 |

380 |

4 |

DN50 |

|

SB200H |

800 |

1405 |

363 |

698 |

4 |

DN200 |

*unit= mm